Topics & News Release

2020/11/10

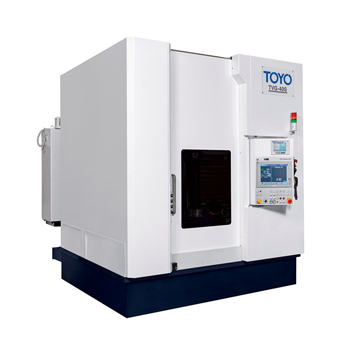

Announcing the Development of the TVG-40S Vertical Composite Grinding Machine Ideal for Machining Medium-Sized and Large Bearings

- Exhibiting the Latest TVG Series Shoe Centerless-Type Machine at JIMTOF2020 Online -

Toyo Advanced Technologies Co., Ltd. (Head office: Minami-ku, Hiroshima City, President: Masahiko Ichida) has developed a brand-new TVG-40S shoe centerless-type machine of the TVG vertical composite grinding machine series, featuring a movable main spindle system. This new model will be on display at JIMTOF2020 Online, which starts on November 16 (Monday).

Based on the excellent customer reviews of the TVG-20S shoe centerless-type machine, designed for machining parts such as small bearings, we decided to develop the TVG-40S, which is ideal for machining large-diameter workpieces, including medium-sized and large bearings.

-

The TVG-40S is a shoe centerless-type vertical composite grinding machine with a compact structure that is only 2,300 mm wide. The machine features a 2-shoe & magnetic chuck, capable of machining large workpieces with a maximum inner machining diameter of φ400 mm. It further enhances all the signature features of the TVG series, including the compact size, high-precision and high-productivity machining, and capability to carry out unmanned and labor-saving operations.

The machine utilizes an independent cutting spindle (X-axis) and table spindle (Z-axis), with the main spindle situated on the X-axis, for a unique movable main spindle system that serves to reduce Z-axis torsion caused by machining loads and provide high-precision machining thanks to a low center of gravity and high rigidity. The X-axis is also equipped with a linear motor, which ensures a high level of precision and high-speed operation.

This compact machine features an ATC (automatic tool changer), an NC swivel, a newly developed NC shoe offset switch, and other devices that achieve high-precision machining of inner diameter, outer diameter, and end faces with a single chuck. The combination of an ATC and NC shoe offset switch significantly reduces the amount of setup and adjustment work in continuous machining of inner and outer diameter surfaces even for workpieces with large machining allowances. The exhibition model will further combine a general-purpose robot, which is suitable for unmanned and labor-saving production lines as it can automatically move heavy workpieces and perform similar operations.

-

◆ High-precision and high-productivity machining

The X-axis of the movable main spindle system is equipped with a linear motor, which is highly responsive and ensures a high level of machining precision. In addition, the NC control system minimizes the synchronization error for the X and Z-axes in order to achieve a high level of taper machining precision.

This compact machine features an ATC that can hold up to five grinding wheels. The maximum grinding wheel diameter is φ255 mm. The ATC can also replace the grinding wheels automatically.

For shoe centerless grinding operations with the 2-shoe & magnetic chuck, the shoes must be rearranged when the machining surface changes because the appropriate position and amount of the shoe offset vary depending on whether you are grinding the inner or outer diameter surface. However, the TVG-40S model does not require rearranging of the shoes thanks to the new NC shoe offset switch that allows you to change the shoe offset position as necessary. When repeating the machining process several times on the inner and outer diameter surfaces of a large diameter workpiece with a large machining allowance, you can adjust the shoe offset position for each machining process. This will allow you to machine the inner diameter, outer diameter, and end faces with a single chuck efficiently and precisely.

◆ Unmanned and labor-saving operations

The exhibition model will feature a large articulated robot. We designed the robot hand to make sure it can attach and remove different types of workpieces. This allows the machine to transport heavy workpieces automatically.

The robot's capability to transport workpieces automatically, the automatic grinding wheel replacement function of the ATC, the automatic shoe offset adjustment function of the NC shoe offset switch, and other features make this machine ideal for building an unmanned and labor-saving production line.

Our booth at JIMTOF2020 Online will include our latest IoT technology and a total of five advanced gear grinder models: the aforementioned TVG-40S, TGG-26-2W gear grinding machine, TVG-20C/S, THG-15S, and T-11JB.