PVD TiC

The high hardness and slipping are the coating by which wear resistance could excel close adherence very highly well.

PVD TiC is a titanium carbide coating made through the PVD process. It combines the benefits of both PVD and CVD, giving it the high dimensional and shape accuracy of PVD along with the greatly increased service life of dies and tooling that is possible with TiC (CVD).

The TiC layer is hard and highly lubricating, making it suitable for punishing die applications such as stamping high-tensile steel plates. Although the adhesion and coverage of PVD are not as good as with CVD, the low treatment temperature of 500°C or less ensures high dimensional stability by minimizing thermal deformation. Therefore, although CVD can provide a longer die service life, the use of PVD coatings for press stamping dies is increasing because of their superior accuracy.

Toyo's new PVD TiC coating is a response to market demand for an exceptionally hard wearing coating for press stamping dies, that also enables high dimensional stability.

Features

PVD TiC forms an exceptionally hard film

(Hv = 3700, on a par with that of conventional TiC).Due to its high hardness and low friction, it has extremely high wear resistance.

It is a high-strength coating with superior resistance against peeling.

The shape and precision can be maintained due to low-temperature processing below 500°C.

Typical applications

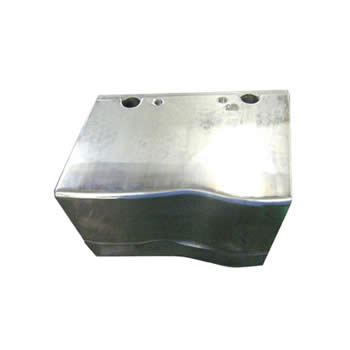

Stamping dies of various types, including:

High-load cold forging dies and tools

Precision roll forming die

Supports high-load such as ultra-high-tensile-strength materials : PVD TiC-X is here