PPD

Dramatically improve the large mold of life, such as an automobile body side type

In PPD treatment, the die itself is hardened at a low temperature of approx. 500 to 550°C (temperature below the transformation point of the base material), so the treatment does not only extend die life dramatically, but also has the advantage of maintaining dimensional accuracy. Furthermore, dies are easily repairable, and unlike plating treatment, PPD produces no waste fluid, both of which contribute to global environmental protection. PPD treatment is far superior to chrome plating treatment in terms of performance.

-

Features

-

The excellent processing power

Superior treatment capacity Because of one of the largest nitriding furnace in Japan, it can simultaneously treat two large dies for body side panels.

-

Longer life of a metallic mold

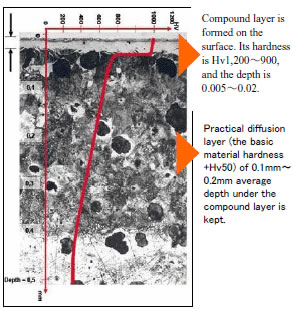

Long die life PPD treatment stably forms a hard compound layer on the metal surface, and a diffusion layer is also formed right beneath the compound layer.

-

Maintenance of shape accuracy

Maintenance of form accuracy Dimensional accuracy is maintained because treatment is done at a temperature lower than the transformation point of the die's base material. Besides, PPD doesn't form membrane.

-

Repair characteristics are good

Excellent reparability It is possible to overlay weld on PPD treated dies directly.

-

Environmentally friendly technologies

Environmentally friendly technology PPD treatment produces no waste fluid, something like a hexavalent chromium.

-

Applications

-

Molds for automobile body steel that are conventionally chrome plated. Metal:FCD, FC

Body side mold

Bonnet mold

-

Hardened layer formed by PPD

-

Material:Ductile cast iron (FCD700)