THG-15S CNC Internal Grinding Machines, Centerless Type

Internal grinder optimally suited for machining bearings and other workpieces that require I.D. and O.D. concentricity.

These machine compatible with automation and enable high productivity and high-precision machining.

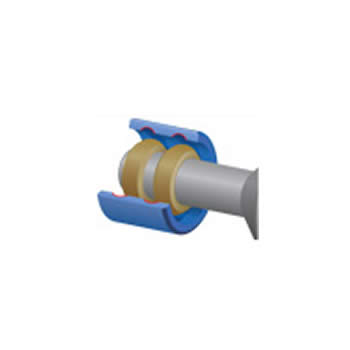

Equipped with one-shoe two-roller or two-shoe magnet type.

We propose the optimal specifications for your workpieces.

Higher precision and consistent production

Thermal deformation is minimized by a bed structure that minimizes the effect of coolant temperature and improved coolant recovery path on the bed.

The machine’ s roller guides with low sliding resistance for the cutting spindle and high-resolution servo motors ensure consistent high-precision machining with a daily dimensional variance of dia. 5 μm or less and a groove position that does not exceed 10 μm. The warm-up time has also been reduced by half compared to the previous model.

Improves productivity

The new NC loader and NC gauges reduce loading times by 30% compared to the previous model. The new machine is non-hydraulic and does not require conventional hydraulic cylinder stroke adjustment, parts replacement, or position adjustment, which reduces the change-over time by half compared to the previous model.

Main Specifications |

THG-15S | ||

|---|---|---|---|

| Workpiece support method | one-shoe two-roller | two-shoe magnet | |

| Loadable workpiece O.D. | φmm | 6~40 | 12~150 |

| Grindable workpiece width | mm | 5~25 | 5~60 |

| Grindable workpiece I.D. | φmm | 6~35 | 6~140 |

| Grindable groove R dimensions | mm | 0~6 | |

| Dimensions(Width×Depth×Height) | mm | 1,980×1,910×1,800 | 1,980×2,090×1,800 |