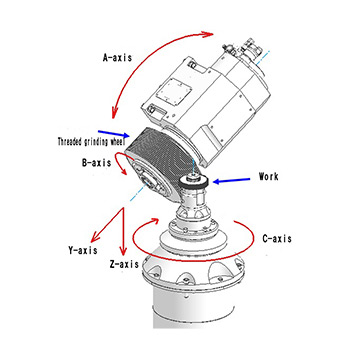

TGG-26-2W Gear Grinding Machine

Gear grinder compatible with workpieces with O.D. of up to 260 mm.

It enables high-productivity and high-precision, stable gear-surface machining.

Higher precision and consistent productivity

Features two work heads for attaching the workpiece, which enable workpiece installation or removal, cleaning, and gear adjustment during machining, greatly reducing the non-grinding time (idol time).

The wheelhead equips with high power built-in motor of 32 kW and enables consistent high-precision machining.

Equipped with an auto-balancer and AE sensor for automatic balance and position adjustment. Its automation made alignment time less.

Dedicated NC system for gear grinders

Equipped with own developed teeth surface correction application to enable ideal gear grinding with simple operation.

Operation screens can be customized according to customer's requirements.

Main Specifications |

TGG-26-2W | |

|---|---|---|

| Grindable workpiece O.D. | φmm | ~260 |

| Grindable workpiece width | mm | ~50 |

| Dimensions (Width×Depth×Height) | mm | 2,440×2,050×2,870 |

《 Gear grinding line proposal 》

Further high-precision machining

Firstly, TVG-20C-2S grinds I.D. and end-face of workpiece, which will be datum of gear, with single chuck. Then, TGG-26-2W performs high-precision machining on the gear surface against its datum. This ensures a highly accurate tooth trace, accumulative pitch, and twist angle.

Long-term unmanned operation

A robot in the machine makes the workpieces loaded, flipped, and air blow. Combined with a workpiece supply unit enables long-term unmanned operation.