PVD: Hard Coating Business

Toward our own business field. The surface treatment technology is very promising.

Product Lineup

-

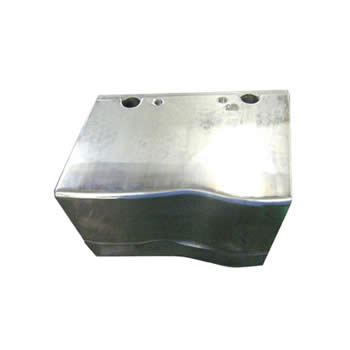

TR-Flat/TR-Flat2

High-heat-resistance coating perfect fit for dies subject to high machining load

-

PVD TiC

PVD is used to apply a titanium carbide (TiC) coating. The resulting TiC layer is very hard and adheres firmly to the target surface.

-

PVD TiC-X

This is a titanium carbide film that was developed by optimizing the film structure of conventional PVD TiC to achieve longer service under high-load press forming conditions, including when processing 1.5 GPa ultra-high-tensile-strength materials.

-

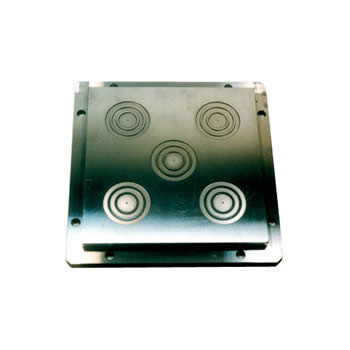

CrN

CrN film with shinny silver color is deposited by the reaction of ionized Chromium and Nitrogen in the plasma atmosphere by PVD method.

-

P-TiCN

PVD is used to apply a hard TiCN layer on top of a layer of TiN. The resulting multilayer coating has the gray-like coloration of titanium carbide nitride (TiCN).

-

TiN

Applied using PVD in a vacuum chamber at low temperatures of 500°C or less. Ionized titanium and nitrogen are accelerated to collide with the target surface to form a titanium nitride (TiN) coating.

-

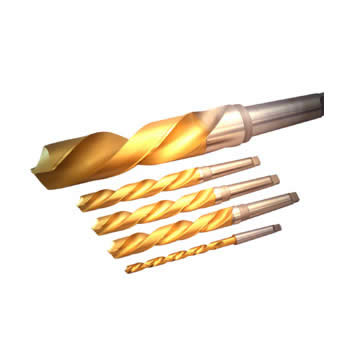

TiAlN

This hard, thin coating can withstand temperatures exceeding 800°C, making it ideal for dry cutting applications.